"Dose-On-Demand" Biomarker Generator by ABT Molecular Imaging

The Biomarker Generator produces PET Biomarkers and Radioisotopes "On Demand" and encompasses an entire PET production lab in a 300 square feet (30 sq meter) room. It includes a self-shielded micro-cyclotron for producing the positron emitting isotopes of F-18 and C-11 and microchemistry system for labeling specific molecules with the positron emitting isotopes. The uniqueness of this system is that it is much smaller than conventional PET cyclotrons, easier to install, and simple to operate.

Simplicity: PET Biomarkers at the Push of a Button

ABT's Biomarker Generator integrates a radioisotope generator, kit based micro-radiochemistry, and automated quality control to provide PET Biomarkers at the user's fingertips.

- Simple GUI interface navigates the user through the production process

- Embedded production and quality control processes minimizes the need for highly specialized staff

- Existing technical staff can operate the system to produce PET Biomarkers

Efficiency: Economic, Rapid Production

Scaled for a single user, the Biomarker Generator is a cost effective solution to introduce or expand the use of PET in your facility

- Single dose production scaled for a single user

- Consumable reagent kits and dose synthesis cards

- Low infrastructure requirements dramatically reduce operating costs

Small Size: Simple Facility Installation

ABT's Biomarker Generator's self-shielding, small size and low power requirements allow for a simple installation with minimal facility modifications

- A complete PET Biomarker Lab in a 30 square meter room

- Self-shielded accelerator and chemistry produces a low radiation burden

- Minimal modifications to the facility for a quick and low cost installation

Flexibility: Biomarkers for Clinical and Research Use

ABT's Biomarker Generator produces the critical PET Biomarker, FDG, for today's clinical needs and is easily adaptable for future radioisotope and PET biomarkers of tomorrow.

- Single dose production of an FDG dose

- F-18 available with C-11 production in development

- Advanced F-18 biomarker capability

Self Shielding

The Biomarker Generator is self-shielded, eliminating the need to provide a bunker for housing the system.

The shield opens vertically for servicing, and provides radiation protection of <1 mR per hour in the typical room size specified. The Micro-Chemistry module is also self-shielded and can be installed adjacent to the cyclotron shield for direct connection within the same room.

Mini-Cyclotron

The Accelerator

- 7.5 MeV Positive ion cyclotron

- 3 internal targets

- Production Rate of 1.0 mCi/min [18F] fluoride

- 1.16 T Magnet

- <5 µA Beam current for F-18 production

Key features

- Low power

- Simple one button operation

- Fast Production - dose when needed

- Designed for reliability

- Access to target and ion source for simple replacement

- Turbo Pump vs. oil based diffusion pump

Micro-Chemistry

- Micro-Chemistry with single use Dose Synthesis Card

- Replaceable precursor/reagent kits

- Programmable and capable of producing any one or two step [18F]fluoride ion based process

- Self-shielded, installed adjacent to the accelerator shield

- [18F]FDG/NaF Module

Requirements

Facility Requirements

- Room vertical height 2.45 m

- Room width and height 5.50 m

Power Requirements

- Electrical Requirements 240 v Single Phase, 70 Amps

Chilled Water System 6 Kw at 16° C

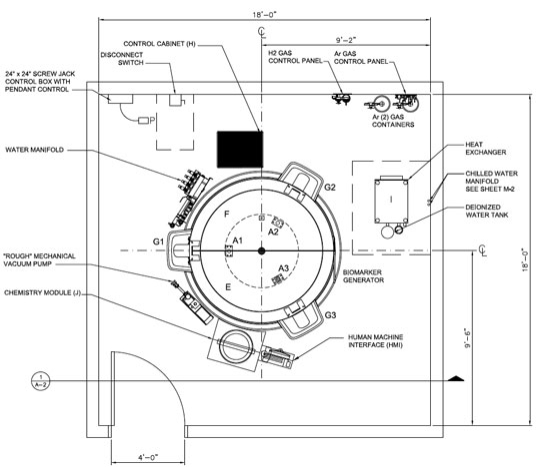

Facility Planning

- 18' x 18' (30 m2) room

- 208V, Single Phase Power

- 4'4" Door Entry

- <1mR per hour at room boundary

Comparison Chart

| Biomarker Generator | Conventional Cyclotron | |

|---|---|---|

| PET Lab Footprint | 300 ft2 | 4,000 ft2 |

| Weight | 24 tons | 50 tons |

| Personnel | 1 FTE | 4 FTE |

| Operating Expenses | $150k/yr. | $600K/yr. |

| Repetitive Production Cycle | 30 min. | 3 hours |